PLAtex

“We believe that everything we do has to generate a positive impact on the environment and improve the livelihood of communities around the world.”

Cotton Purge

Cotton fabric in its loom-state contains impurities and requires further treatment to be ready for the dyeing step. Traditional cotton cleaning and preparation involve then the use of different chemical agents.

PLAtex replaces traditional purge of cotton and viscose making the preparation a sustainable, chemical-free and water-free process.

Advantages:

- Sustainable process (totally dry)

- Integrable in dyeing process (in-line)

- The compact design of the plasma machine (PLAtex)

Polyester scouring

Polyester fabrics at loom state have grease and stains that need to be scoured before heat-set and dyeing/printing process, to avoid stiffening and disuniformity.

PLAtex can effectively replace the polyester scouring process, eliminating completely the use of chemicals and detergents and reducing up to 100% the water consumption.

Digital printing & plain dyeing

PLAtex can be used for polyester preparation for digital printing and plain dyeing (direct dyes). PLAtex guarantees the effective replacement of traditional foulard (with chemicals) with a water-less process that ensures: no bleeding, higher definition, brilliant colors and modulation of color penetration.

Rotary printing preparation

Other than for digital printing, PLAtex can be used to replace rotary printing traditional preparation (replaces foulard). The process with PLAtex is 100% dry, uses 99% fewer chemicals, 90% less energy consumption and guarantees zero toxic discharges.

Anti-stain finishing

Anti-stain finishes have become the most important repellents of stains and dirt used on clothes, carpets, upholstery, draperies, leather and other household fabrics.

Currently, the resin is applied by foulard/padding onto fabric, followed by drying (≃120°C) and curing (>150°C).

Using PLAtex it is possible to transform anti-stain finishing in a sustainable, water-free and less energy-consuming process.

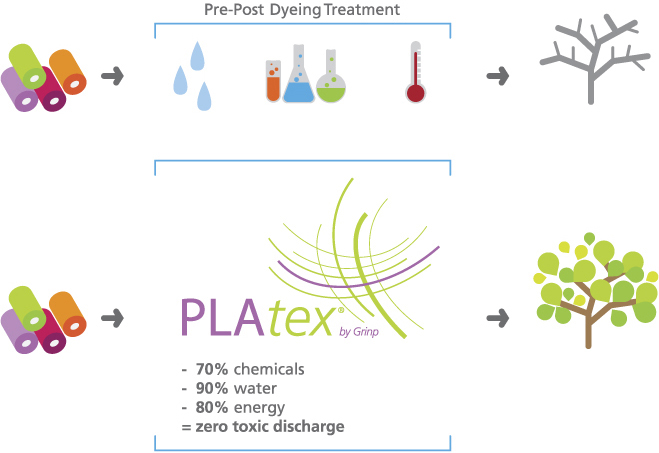

In conclusion, this is what happens to the environment when traditional processes are used…

…and this is how better it can be using PLAtex!

PLAtex INDUSTRIAL

We offer a series of versatile machines for industrial use.

Our PLAtex industrial machines are fully automatic to ensure easy usability and can be easily integrated into production lines.

Upon request of the client, our PLAtex machines can be designed to be integrated with existing production lines or equipped with best quality roll to roll systems to stay off-line (also suitable for integration at a later stage).

PLAtex industrial machines are modular and two or more modules can be paired to reach high speed. The speed is always strictly related to the process and the number of modules.

Since 2012 some companies in the textile industry are regularly using our machines for the industrial treatment of fabric with sustainable processes.

Available machines:

- PLAtex 1000 HT (for fabric up to 1m wide, energy consumption 10-15 kW)

- PLAtex 2000 HT (for fabric up to 2m wide, energy consumption 25 kW)

- PLAtex 4000 HT (for fabric up to 4m wide, energy consumption 40 kW)

All PLAtex industrial machines meet Industry 4.0 requirements

PLAtex LABORATORY

We offer a series of versatile machines for laboratory use.

Our machines PLAtex LAB can be automatic or manual for easy management of plasma parameters.

Since 2010 some of the most important universities, research and technological centers around the world are studying plasma and its possible applications using our laboratory machines.

Available machines (energy consumption 3-5 kW):

PLAtex 400 LAB (for fabric up to 400mm wide)

PLAtex 600 LAB (for fabric up to 600mm wide)

PLAtex 1000 LAB (for fabric up to 1000mm wide)

“We believe that our business must pursue innovation as a means of preserving life on this planet .”

For more information please contact with us